Ioniqa, één van onze Nationale Iconen, ontwikkelt een nieuwe chemische upcyclingsmethode. Het eindproduct is een hoogwaardige grondstof gelijkwaardig aan nieuw plastic uit olie. Daarmee kan 25 procent van de wereldwijde plasticproductie oneindig worden hergebruikt, met 75% minder CO2 uitstoot. Dankzij de Corona OverbruggingsLening (COL) is de startup na de coronacrisis weer snel uit de startblokken om de groeiende plasticberg op te ruimen.

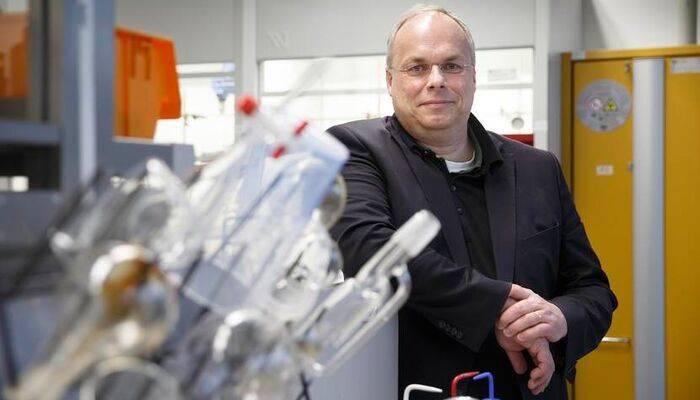

Ioniqa werd in 2009 opgericht als spin-off van de Technische Universiteit in Eindhoven, waar alle R&D plaatsvindt. “We hebben inmiddels ook twee productiefaciliteiten”, zegt Tonnis Hooghoudt, een van de oprichters. “Die staan op Chemelot, het industriecomplex voor de chemische industrie in Geleen, en in Rotterdam, waar we onder andere samenwerken met Unilever in een demonstratiefabriek. De grondstoffen die we met ons gepatenteerde proces maken, voldoen aan de hoogste eisen. Ze zijn geschikt voor voedselveilige verpakkingen.”

De haperende economie heeft ironisch genoeg de plastic afvalberg juist groter gemaakt. Het is op het moment goedkoper om uit ruwe olie nieuw plastic te produceren dan om het te recyclen. Maar dat is een tijdelijk probleem, denkt Hooghoudt. “Onder druk van consumenten, CO2 belasting en steeds strengere wetgeving, werken alle grote fabrikanten aan plannen om uiteindelijk helemaal circulair te worden. Onze techniek sluit de cirkel en gaat een belangrijke rol spelen bij de productie van plastic.”

“We zijn in de ontwikkeling van ons bedrijf wel vaker met verrassingen geconfronteerd. Ook deze crisis blijkt niet desastreus. Maar met de Corona OverbruggingsLening konden we voorkomen dat we problemen kregen met onze cashfow. De vaart waarmee de regeling is aangekondigd en uitgevoerd, heeft ons veel rust gegeven en ruimte om te ademen. Ik ben echt onder de indruk van de voortvarendheid en het gemak waarmee de regionale ontwikkelingsmaatschappijen hebben samengewerkt. Daar had ik een heel ander beeld van.”

Hooghoudt: “Een crisis als deze zet je wel aan het denken. Sommige veranderingen zullen blijvend zijn. Maar ónze plannen blijven ongewijzigd. We werken aan een proces om naast PET uit verpakkingsmateriaal ook polyester uit textiel te kunnen upcyclen. De fabriek in Geleen gaat ook weer op volle toeren draaien. Maar dat is pas het begin. Ons doel is dat fabrikanten overal ter wereld in licentie soortgelijke fabrieken gaan bouwen. Onze technologie wereldwijd beschikbaar krijgen, daar draait het om bij het opruimen van de plasticberg. De techniek werkt. Dat hebben we inmiddels laten zien.

- Jaarlijks gaan in Nederland zo’n 900 miljoen kleine PET-flesjes over de toonbank. Naar schatting belandt zo’n 100 miljoen daarvan in het milieu.

- Door op 1 juli 2021 een statiegeldsysteem voor kleine flesjes in te voeren wil staatsecretaris van Veldhoven plastic flesjes uit het milieu weren.

- De inschattingen zijn dat met dit statiegeldsysteem 90% van de plastic flessen gerecycled kan worden.