In Eindhoven zit het super gespecialiseerde laboratorium van Altum RF (gevestigd in hub Twinning van Twice Eindhoven op de TU/e Campus). De naam staat zoals te verwachten voor ‘hoge radiofrequenties’. Want dat is wat ze doen bij Altum RF: ze ontwikkelen piepkleine chips voor antennes die signalen kunnen opvangen en versterken, die via hoge frequenties uitgezonden worden.

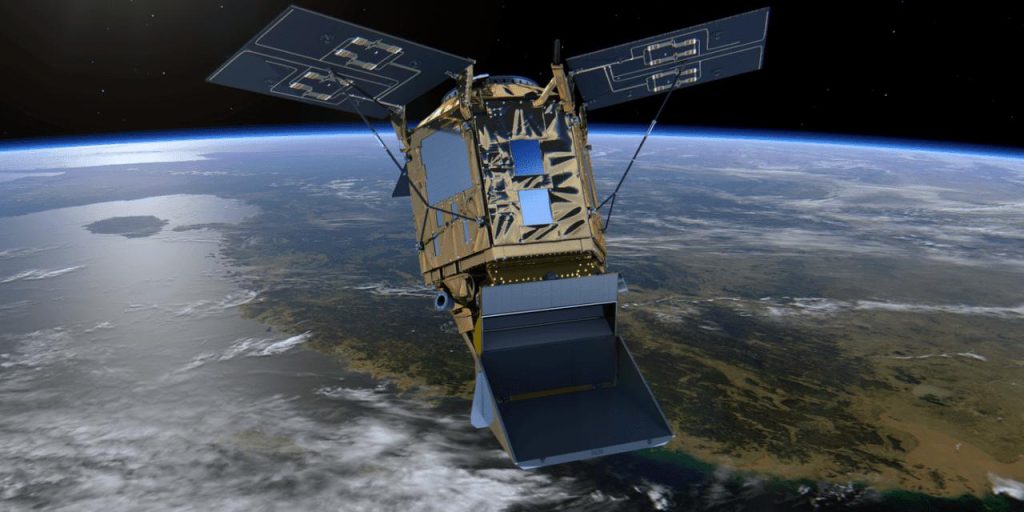

Denk bijvoorbeeld aan signalen die satellieten uitzenden, of aan signalen die straks gebruikt worden om supersnel data te kunnen versturen en ontvangen via de nieuwe frequentieband van 5G tussen 26,5 en 29,5 gigahertz die vanaf 2025 beschikbaar zal zijn.

Super korte golflengtes

Het probleem dat je met zulke hoge frequenties hebt, is dat de lengte van de golven kort is, zegt Niels Kramer, directeur van Altum RF. Die van een frequentie van 30 gigahertz bijvoorbeeld is maar een centimeter. Hoe hoger de frequentie, hoe korter de golf. Nu zou je denken: wat maakt dat uit? Een van de problemen die dat oplevert, is dat de elektrische signalen die via die hele hoge frequenties overgebracht worden makkelijk gedempt worden, en dat de afstand tussen de antenne en de versterker-chip die daaraan gekoppeld is, niet te groot mag zijn.

Gallium

Het gebruikelijke materiaal voor chips, silicium, is daarom niet geschikt. Dat dempt elektrische signalen die via de hoge frequenties overgebracht moeten worden teveel. Daarom gebruikt Altum RF galliumnitride, een halfgeleidermateriaal van gallium (een metaal dat onder andere uit steenkool gewonnen kan worden) en stikstof. Gallium kan voor het maken van dit soort chips ook aan arseen gebonden worden. Dan heet het galliumarsenide.

Een voordelige eigenschap van dit materiaal is dat elektronen er makkelijker in bewegen dan in silicium en dat het nog beter geleidt. Dat versterkt de elektromagnetische golf waardoor het signaal en de energie ervan niet verloren gaan. De elektrische doorslagspanning is bovendien een stuk hoger dan van silicium. „Met silicium zou het signaal niet zoveel versterkt kunnen worden als met gallium”, aldus Kramer. Veel keuze was er dus niet.

Satellietcommunicatie

Voor sommige van dit soort actieve antennes kunnen wel duizend van die chips gebruikt worden, zegt Kramer. „Voor satellietcommunicatie bijvoorbeeld. We werken ook voor de ESA.”

Het nadeel van galliumnitride is dat het erg duur is. Het zal dan ook niet gebruikt worden voor de productie van mobiele telefoons. Het zullen de grote telecombedrijven zijn die de chips in grote hoeveelheden zullen bestellen voor de productie van basisstations voor de hoge frequentieband van 5G. „We hebben inmiddels prototypes opgestuurd naar meerdere klanten. Die zijn nu aan het testen of ze goed in hun systeem functioneren.”

De 5G-chip was in twee jaar klaar, zegt Kramer. Al met al een klus die dus te overzien was. Hoe snel Altum RF een 6G-chip kan ontwikkelen, zal blijken als zich een klant aandient die deze snel wil hebben, zegt Kramer. Eerder begint hij er niet aan.

6G-chip in pril stadium

Het project van de TU/e dat zich hier in samenwerking met elektronicafabrikant NXP mee bezig zal houden, MyWave, is desalniettemin in april van start gegaan.

De uitdaging waarvoor dat team staat is gigantisch. Omdat 6G vanaf 2030 waarschijnlijk gebruik gaat maken van frequenties hoger dan 100 gigahertz, waarvan de lengte dus heel kort is, moet de weg die deze aflegt naar de antenne dus nog korter worden dan in de 5G-chip. „We denken dat de antenne in de chip geïntegreerd moet worden. Anders kan het niet. Je komt dan weer hele nieuwe problemen tegen.”

Of dit klusje binnen twee jaar gepiept zal zijn, durft Kramer niet te voorspellen. Maar dat het ze zal lukken om zo’n antenne-op-chip te maken, is wat hem betreft zeker. „Dit gaat gebeuren.”