Lake3D, specialist in driedimensionale druktechnologie, en gevestigd in hub Beta, bestaat nog maar een jaar of anderhalf. Na een periode van laboratoriumtesten op diverse locaties zal de startup volgend jaar de eerste proefseries gaan maken vanuit een nieuwe productielocatie in Maastricht met vooralsnog focus op de tandheelkunde. LABInsights interviewde het team en schreef dit artikel.

Lake3D is in de basis een Limburgs bedrijf met een vestigingen op Twice in Eindhoven, de Brightlands Campus Geleen, en in Parijs! Reden: de diversiteit van de activiteiten die onmogelijk allemaal op één plek uitgevoerd kunnen worden. “Als specialist in het 3D-jetten van allerlei materialen in alle kleuren hebben we een brede technologieportfolio”, verklaart Chief Technology Officer (CTO) Joost Anne Veerman. “Die omvat elektrotechniek, mechatronica, software, chemie en fysica.” Dat maakt veel verschillende laboratoriumtesten op diverse locaties heel logisch.

Wij bouwen producten op uit druppeltjes van 25 micrometer (μ), uit maximaal acht verschillende materialen.

CHIEF TECHNOLOGY OFFICER (CTO) JOOST ANNE VEERMAN

Proefserie

Volgend jaar zal Lake3D de eerste proefseries gaan maken vanuit een nieuwe productielocatie in Maastricht. “Stel je geen grote kantoren voor, het gaat vooral om labcapaciteit”, relativeert Veerman. “Het werken op verschillende locaties past wel bij een hightech start-up anno 2021. Wij bouwen met onze eigen printerproducten op uit druppeltjes van 25 micrometer (μ), uit maximaal acht verschillende materialen. Die vormen na uitvloeiing laagjes van 10 μ. Dat doen we met verschillende printkoppen in een modulair opgebouwde printer. Dit verklaart waarom we kennis uit zoveel disciplines integreren en op gespecialiseerde locaties testen.”

Procesontwikkeling

Het 3D-jetten uit verschillende materialen om de juiste functionele eigenschappen in een eindproduct te krijgen, is niet zomaar een kwestie van een printer met printkop samenstellen en op de knop drukken. Veerman: “Allereerst ontwerpen we zelf de machine. Dat doen we modulair, zodat we makkelijk de printkop kunnen wisselen en naar wens randapparatuur voor bijvoorbeeld UV-uitharding kunnen toevoegen.” Maar een printer alleen is niet genoeg, het gaat per product ook om de procesontwikkeling, met name op het punt van de interactie tussen materiaal en printkop. Veerman: “De omstandigheden tijdens het printen zijn van groot belang en de eisen aan de eindproducten zijn hoog. Als je gaat produceren, moeten de productieomstandigheden blijvend stabiel zijn om de juiste kwaliteit eindproduct te krijgen. Zover zijn we nu nog niet. Tot die tijd is het: testen, testen, testen en meten, meten, meten.”

SEM

Zo maakt Lake3D gebruik van het DSM Science Centre op de Brightlands Campus Geleen voor bijvoorbeeld Scanning Electron Microscope (SEM)-onderzoek of Micro Computed Tomography (micro CT)-scans. Daarnaast voeren mbo, hbo en wo-studenten onder leiding van een supervisor van Chill op die campus kleur-, sterkte- en hardheidsmetingen uit aan de geprinte producten. Andere metingen betreffen de biocompatibiliteit van materialen. Lekt er bijvoorbeeld materiaal uit een polymeernetwerk weg? Zitten bij gevulde materialen de nanodeeltjes veilig in de matrix?

Printstrategie

In Parijs zit de groep die verantwoordelijk is voor software-architectuur en -design. Op de Brightlands Campus in Geleen en de High Tech Campus in Eindhoven zijn de eigenlijke test- en ontwikkellaboratoria gevestigd. Daar ontwerpt Lake3D met de materialen van een Europese ontwikkelpartner zijn producten op het printplatform. Hier ontwikkelt het bedrijf de printstrategie: hoe bouw je de laagjes op? Vloeistofreologie om het vloeigedrag van druppeltjes tot laagjes te bestuderen is een belangrijk onderzoeksterrein. Hetzelfde geldt voor 3D-kleuropbouw: welke kleur moet op welke diepte komen om het juiste effect te bereiken? Lake3D past ook optische microscopie en visioncamera’s toe om beide processen tot in het kleinste detail te kunnen analyseren.

Geautomatiseerde kronenproductie

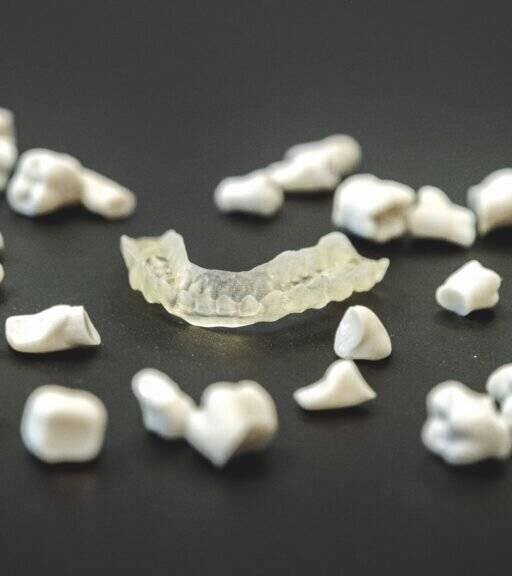

Het aantal mogelijke applicaties is groot. 3D-jetten maakt het mogelijk om de gewenste eigenschappen van verschillende materialen te combineren. Dat is in veel specialisaties aantrekkelijk. “Focus is belangrijk: de applicatie(s) selecteren waarin we functioneel de meeste toegevoegde waarde hebben”, geeft Veerman aan. “Daarom hebben we gekozen voor tandheelkundige oplossingen, zoals kronen, snurk- en anti-knarsgebitjes. Daarbij werken we samen met universitaire opleidingen tandheelkunde en een aantal tandheelkundige laboratoria.”

Verschillende keramieksoorten

Als marktintroductie aan de orde komt, kan Lake3D bijvoorbeeld de geautomatiseerde productie van kronen in de gewenste vorm, kleur en hardheid realiseren. Nu is dat nog handwerk, maar voor het maken van modellen is deze markt wel vertrouwd met 3D-printen. Veerman: “Wij zetten de stap naar geprinte permanente oplossingen. De huidige zirkoniumkronen zijn tien keer zo hard als de natuurlijke tanden, waardoor die harder slijten. Bovendien hebben die een extra kleurlaagje van porselein nodig. Doordat wij verschillende keramieksoorten kunnen mixen, kunnen we exact de juiste hardheid maken. Daarnaast kunnen we niet alleen de kleur van het natuurlijke glazuur, maar ook het halftransparante karakter van dat materiaal in één printbewerking tot stand brengen: hard en zacht, de juiste kleur en de juiste lichtdoorlatendheid ineen.”

Digitaliseren van tandheelkunde

Lake3D zou met een voor het proces ontwikkelde printer en software weleens het eerste bedrijf ter wereld kunnen worden dat met een commerciële toepassing van 3D-jetting op de markt komt. Veerman: “Digitalisering van de tandheelkunde is het eerste, maar nadrukkelijk niet het enige toepassingsgebied.” Het lastige is wel, dat Lake3D vooral een latente behoefte kan vervullen. “Wij kunnen oplossingen bieden en producten maken die op een andere manier niet mogelijk zijn: zeer nauwkeurig, mogelijk heel klein, uit materiaalcombinaties die nu nog niet bestaan. Dat betekent dus dat wij aan prospects duidelijk moeten maken dat wat zij niet voor mogelijk houden, wel degelijk kan. Daar hebben we een mooie uitdaging aan.”